Our Services

Section

Bending

Plate Rolling

& Welding

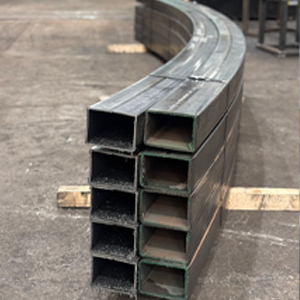

Section Bending

Section Bending was the first service to be offered when Barnshaws started in 1969. We now have the leading capacity worldwide in section bending and our experience gives customers the confidence to design structures with minimal limitations. We offer services of bending sections up to 35m long, as a one off or supplying large volume orders.

Plate Rolling & Welding

Our modern machines allow Barnshaws to roll plates up to 100 mm in thickness and up to 4500 mm in length. Thanks to our state of the art welding equipment we provide comprehensive solutions for cylinders and silos. With our great experience working on top level projects over the years we’ve taken a leading role in the plate rolling sector across all Europe.

Press

Braking

Induction

Bending

Press Braking

Thanks to the largest range of press braking facilities in the UK, we specialise in bending components up to 12 m long and up to 80 mm thick. With various profiling machines, including one of the biggest laser cutting machine in the UK, Barnshaws can provide a comprehensive service to all industries.

Induction Bending

Induction bending offered at Barnshaws is an advanced metal bending process, offering reliable precision, good efficiency and excellent consistency to a highest standard. The process is suitable for a wide range of applications such as oil and gas pipelines where it is mandatory to overcome the limitations of cold bending techniques.

Aluminium

Bending

Tube & Pipe

Bending

Aluminium Bending

Barnshaws have a wide range of machinery for bending aluminium and non-ferrous sections, extrusions and sheet metal. We specialise in bending various bespoke architectonical and automotive sections with very complex shapes based on our Customers requirement.

Tube & Pipe Bending

There are many different methods of tube and pipe manipulation and at Barnshaws we perform most of them. As the world's largest metal bending company, we have an outstanding long term record of achievements in various sectors like construction, oil and gas, offshore, mining, transport and many others

Section Bending

Section Bending was the first service to be offered when Barnshaws started in 1969. We now have the leading capacity worldwide in section bending and our experience gives customers the confidence to design structures with minimal limitations. We offer services of bending sections up to 35m long, as a one off or supplying large volume orders.

Plate Rolling & Welding

Our modern machines allow Barnshaws to roll plates up to 100 mm in thickness and up to 4500 mm in length. Thanks to our state of the art welding equipment we provide comprehensive solutions for cylinders and silos. With our great experience working on top level projects over the years we’ve taken a leading role in the plate rolling sector across all Europe.

Press Braking

Thanks to the largest range of press braking facilities in the UK, we specialise in bending components up to 12 m long and up to 80 mm thick. With various profiling machines, including one of the biggest laser cutting machine in the UK, Barnshaws can provide a comprehensive service to all industries.

Induction Bending

Induction bending offered at Barnshaws is an advanced metal bending process, offering reliable precision, good efficiency and excellent consistency to a highest standard. The process is suitable for a wide range of applications such as oil and gas pipelines where it is mandatory to overcome the limitations of cold bending techniques.

Aluminium Bending

Barnshaws have a wide range of machinery for bending aluminium and non-ferrous sections, extrusions and sheet metal. We specialise in bending various bespoke architectonical and automotive sections with very complex shapes based on our Customers requirement.

Tube & Pipe Bending

There are many different methods of tube and pipe manipulation and at Barnshaws we perform most of them. As the world's largest metal bending company, we have an outstanding long term record of achievements in various sectors like construction, oil and gas, offshore, mining, transport and many others

News Stories

03

Jun

Structural Engineers should be aware of the material property changes that occur in the bending process of steel sections.

In the case of cold bending, it relates to the strain that occurs when a section is bent (curved) as the outer surface expands and the inner surface of the bend contracts. Read More...

21

May

What Is Cone Bending?

Cone bending is a specialist metal forming process that shapes flat sheet metal or plate into a conical form – a structure that gradually narrows from a wide base to a smaller top. It is an essential fabrication technique widely applied across industries requiring cone-shaped components. Read More...

24

Apr

When Craftsmanship Meets Artistry: Barnshaws’ Precision Bending for Elegant Lighting

Precision Brass Bending for Bespoke Lighting: This project involved a large order of 50 x 25 x 1.5mm Brass RHS (Rectangular Hollow Section), rolled to a 475mm inside radius. While the specification may appear straightforward, bending such a thin and malleable material without causing deformation was a significant challenge. Read More...

British & European Steel Sections

View Our New Handbook

Gallery

-

The Big One

Case Study -

Francis Crick Institute

Case Study -

Manchester Victoria Station

Case Study

Join Our Mailing List

Please enter your email address below to receive news and updates from Barnshaws